heating system

Each central heating system consists of a heat source, a characteristic pipe system for heat distribution and a heating element. Special heating systems consist of a heat source and a heating element, which are built into one device and are located directly in the heated interior.

The heating element transfers the required amount of heat to the given environment, thus ensuring the optimal internal temperature of the room, which is given by STN EN 12831 or the user's need. An optimal heating system creates economic conditions for heating, i.e. j. for economic operation, investment costs, material availability, convenient assembly and maintenance during operation, as well as the possibility of prefabrication. The decisive criteria for the correct choice of the heating system are the characteristics of the operation, the nature and type of the building, its thermal technical and storage properties and the possibility of regulating the system.

The complex requirements for reducing the energy demand of buildings are closely related not only to the technical solution, but also to the environmental impact of the environment and economic efficiency. Each object must be assessed from several aspects and independently. The energy demand of the building is determined by a large number of marginal conditions from the external and internal environment, as well as the nature of the operation of individual devices ensuring the necessary quality of the microclimate in the building. We could divide these boundary conditions into five groups:

climatic conditions,

architectural solution of the building,

thermal technical properties of constructions,

the impact of environmental technology equipment,

the impact of operation and maintenance.

Central heating systems

Central (central) heating of buildings is characterized by the production - preparation of a heat-carrying substance in a central heat source, in which the energy from the fuel is converted into heat and transferred to the heat-carrying substance. With the help of horizontal and vertical pipelines, this is transported to the heating elements, which supply heat to the heated space.

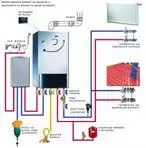

A classic heat source can be placed in the basement (stationary gas boilers, solid fuel or biomass boilers) or directly in some room of the building (wall-mounted combined gas boilers) (Fig. 1). In the boiler, the heat-carrying substance is heated, which reaches the heating elements through the pipe distribution. These heat the air in the interior and ensure a thermal balance between heat losses and heat gains. The circulation of the heat-carrying substance is natural, the so-called gravitational or forced, where circulation is provided by a circulation pump. The heat source can also use renewable energy sources, especially solar energy, and heat from surrounding surfaces

Depending on the type of heat-carrying working substance used for the selected heating system, it is usually:

steam or hot water heating - it is mainly used for heating large-scale buildings, such as industrial, sports and exhibition halls, hangars, warehouses, etc.

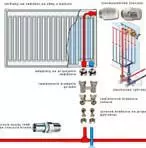

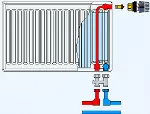

hot water heating – thermal comfort is ensured by a hot water heating system with a temperature gradient of 90/70 °C, or another, e.g. 80/60 °C, and classic heating elements (Fig. 5). The distribution pipes from the heat source to the heating elements are on the lowest floor (under the ceiling of the basement or ground floor), or they are built into the hot water channel, or directly into the floor layer. The circulation of the heat carrier can be with natural circulation, or with forced circulation with the help of a circulation pump located behind the boiler, or directly in the boiler. The average temperature of the heating elements is 80 or 70 °C;

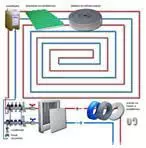

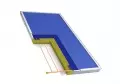

low-temperature heating (Fig. 6) – thermal comfort is ensured by a heating system with low-temperature radiant floor surfaces with a temperature gradient of 45/30 °C or wall (ceiling) surfaces with a temperature gradient of 60/40 °C. The heat source works with a temperature gradient of 90/70 °C or 80/60 °C. The treatment of the heat-carrying substance is carried out in the mixing fitting, and the circulation of the working substance is ensured by the circulation pump. The treatment of the heat carrier can also take place in a special heat exchanger. The heating surface consists of the floor or a wall where steel, copper or plastic pipes are embedded. The surface temperature of the floor during underfloor heating is max. 28 to 29 °C, with wall heating up to 40 to 50 °C

combined heating (Fig. 8) - a combination of the described heating systems is used, e.g. hot water heating with a temperature gradient of 90/70 °C and low-temperature radiant floor heating with a temperature gradient of 45/30 °C. As a rule, each circuit has a separate pump and the temperature of the working substance is adjusted by mixing fittings depending on the outside temperature, this is the so-called equithermal regulation.

Local heating systems

In local heating systems (Fig. 9, Fig. 10) the heat sources are placed directly in the heated rooms and at the same time have the role of heating elements. This heating method is suitable for objects that have two to three rooms in which local heat sources are used, or for large-scale objects. It is the easiest way to ensure thermal comfort in a heated room.

The heat source (at the same time, the heating element) transmits heat to the space:

convection – heats the surrounding air and causes it to move,

by radiation - the surrounding surfaces are heated.

Even local heating systems can be combined, e.g. gas infrared heaters and gas air handling units.

Underfloor heating comes closest to ideal temperature distribution in the vertical direction. According to the type of fuel used, or energy, we distinguish special heating systems with a heat source into:

solid fuel (soft and hard wood, brown coal, briquettes, coke)

liquid fuel (light and heavy heating oil),

gaseous fuel (natural gas, biogas, propane, butane),

electrical energy (direct heating, storage, mixed).