condensing boiler

It is a boiler that uses the so-calledmode of condensation of water vapor contained in flue gases. The condensing boiler also uses the heat contained in the flue gas, which would otherwise go out through the chimney. If we lower the temperature of the flue gas in the boiler below the dew point (the so-called condensation point), the heat of condensation of water vapor is released in the boiler exchanger.

A condensing boiler is not a perpetual motion machine or an inexplicable technology. It is the result of the requirement for the highest possible efficiency when burning gas. Non-condensing technology is going into history, and today the most common condensing boiler is for direct gas combustion. To better understand how it works, here are the basic facts.

The designation of the boiler as "condensing" is based on the condensation (precipitation) of water vapor from the flue gas. When burning natural gas with air, the flue gases contain two main components: CO2 and water.

Water is contained in the flue gas in the form of water vapor.In the past, this water vapor could not be used, and therefore it was futilely discharged into the air through a chimney. The flue gas temperature ranged from 120 to 180 °C.

The rising price of fuel created pressure for the highest possible efficiency when burning gas.

The logical step was to use this water vapor from the flue gas.

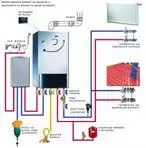

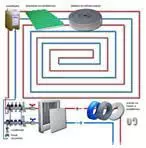

This was achieved by structural changes to the boiler, namely:

– by adapting the burner and exchanger so that water can be found directly in the combustion space,

– by connecting the combustion chamber through a siphon to the sewer for draining condensate,

– by adjusting the chimney part for the presence of water.

This is how the condensing boiler was created. The temperature of the flue gas dropped to values from 40 to 65 °C.

The overall efficiency of the boiler was increased by the following components:

Heat obtained by condensation 11% + Reduction of flue gas temperature 7% = increase in efficiency by 18%.

In the past, condensate energy was not taken into account, and therefore, from a mathematical point of view, today the efficiency of the boiler is up to 108%. However, if we think physically about all the energy contained in natural gas, the efficiency of the condensing boiler is 98%. The overall efficiency is also affected by the correct assembly, which you can read more about in the article.

At first glance, the design of classic and condensing boilers is exactly the same for many manufacturers. An inexperienced customer will not know the difference.

But the first difference is the price. Due to its design, a condensing boiler is more expensive than a simple atmospheric boiler.

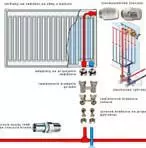

The second difference is the already mentioned drainage of condensate (usually through a pipe from the boiler in the lower part). The third difference is the design of the chimney, where a plastic polypropylene pipe is used for the condensing boiler. A condensing boiler always has a fan, because the flue gas temperature is low and the chimney would not have enough draft.

However, fans are also installed in classic boilers, so-called turbo. They also serve to overcome the resistance of the chimney part. Therefore, there is no need to be tempted by the low price of a classic turbo boiler, the operating costs will "pay back" the price difference in just a few years.